FPT Industrial Leads the Way at Powergen International Exhibition in the USA. The event, held at the end of January in New Orleans, focuses on energy production systems and attracted companies and professionals from 90 countries in its latest edition. As the main sponsor of the 2024 edition, FPT Industrial took center stage by showcasing its entire range of engines, from the “F34” units with 55 kilowatts of power to the “Cursor 9” units with 388 kilowatts. Common to all systems is the “plug-and-play” approach, embraced to create pre-assembled and pre-validated generation solutions whose design facilitates implementation in diverse contexts.

Ftp industrial “G-Drive”: Integrated After-treatment Systems

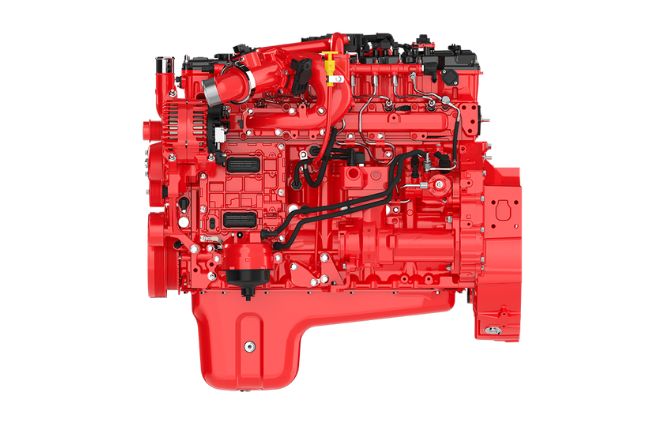

A significant advantage comes not only from the compact size of the engines but also from integrated after-treatment systems that require no maintenance and can be installed horizontally or vertically. It’s worth noting that these features do not negatively impact operational costs, as demonstrated by the low fuel consumption of the “F34” units, showcased at the event in “Tier 4 Final” certified versions with power ratings of 55 and 90 kilowatts, capable of providing up to 41 and 75 kilowatts of electricity at 60 hertz continuously and with variable loads. The four-cylinder, three-liter, and 400 cubic centimeter engine feature an optimized after-treatment system without a DPF filter and boast an operational interval of 600 service hours between maintenance intervals. Alongside the “F34” units, the four-cylinder, in-line “F36” series engine, certified in Tier 4 Final with a power rating of 105 kilowatts, was also on display.

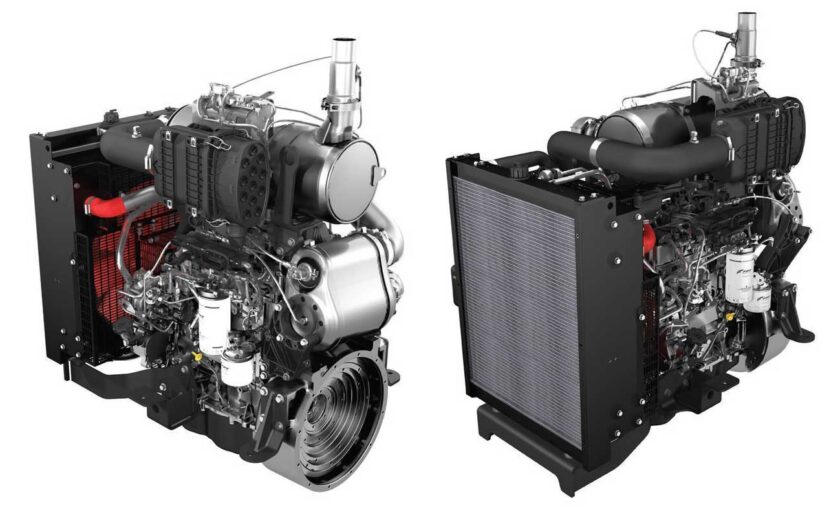

Ftp industrial “G-Drive”: Increased Power Density

Smaller in size than the “F34,” the “F36” engine offers superior performance and is characterized by a higher power density, a feature facilitated by an after-treatment system for exhaust gases, “Hi-eScr2,” allowing compliance with current regulations without requiring EGR systems. This characteristic is shared by the “Nef45” unit with 102 kilowatts of electrical power output at 60 hertz, available with both electronic and mechanical injection systems. Both ensure low operating costs whether operating at 1500 rpm for energy production at 50 hertz or at 1800 rpm for energy production at 60 hertz. Designed for more demanding applications, the “Nef67” unit was showcased with a power rating of 230 kilowatts in Stage V and Tier 4 Final certification, allowing compliance with both emission standards without modifying the unit’s layout. With a displacement of six liters and 700 cubic centimeters and a six-cylinder in-line architecture, it generates 186 kilowatts of power at sixty hertz.

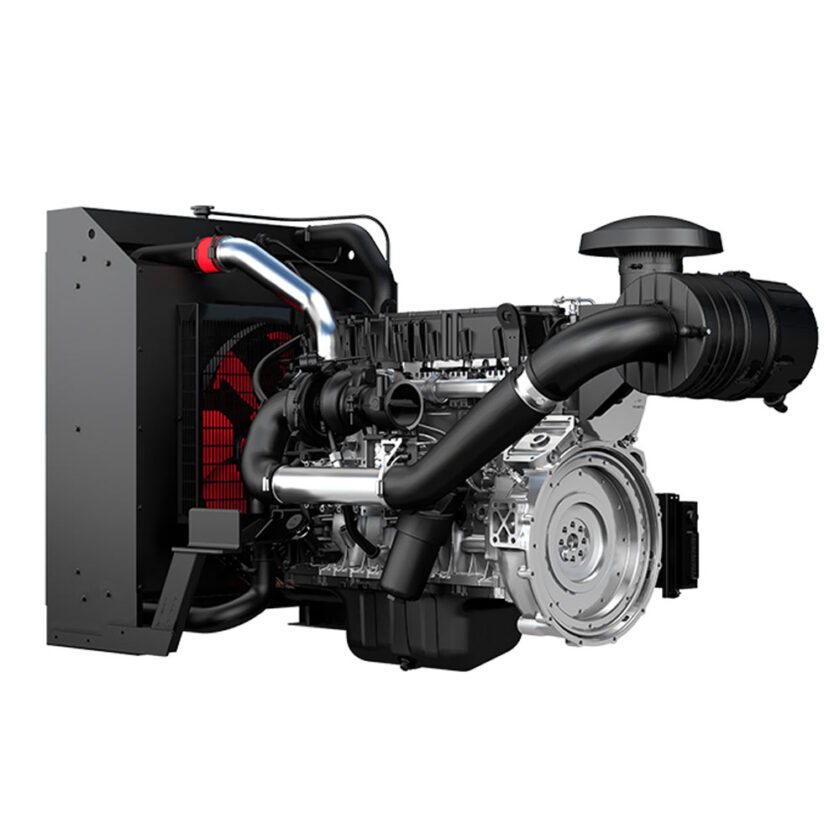

Up to 276 Kilowatts at 60 Hertz

Closing the lineup is the “C9,” also available with dual certification in Stage V/Tier 4 Final. It was showcased with a power rating of 388 kilowatts, capable of delivering 276 kilowatts of power at 60 hertz. With a displacement of eight liters and 700 cubic centimeters, it, like the “Nef67,” can operate at the most functional regime to meet network demands.

The 16-liter Engine

In addition to the units presented at Powergen International, FPT Industrial offers a range of “G-Drive” power groups based on a 15-liter and 900 cubic centimeter “C16” unit. It delivers 568 kilowatts of power, and in the future, the group will be enhanced with the introduction of the latest version of the “C16” with single and dual turbocharger options. The new power units will feature designs without EGR and the “Hi-eScr2” after-treatment system to reduce operating costs with a flexible layout adaptable to different certification standards.

Translation with ChatGPT